Services

Electrical Safety

Electrical Safety

Ensure The Safety Of The Electrics In Your Business & Building

Reliable Electrical Testing For A Safer & More Efficient Site

You have a responsibility to your staff, customers and others to maintain the safety of your building and the items within it. Your electrical safety should be paramount – after all, it is what keeps your people safe and is required by your insurance company.

At Ultimate Compliance, our customers rely on us to provide trustworthy and thorough electrical safety services. Whatever your needs, from PAT testing to load analysis, we ensure a high quality of work without any stress or hassle using our simple-to-use customer portal that lets you track communication and see updates.

Why Choose Our Electrical Safety Services?

Simple Quoting Process

Know exactly what you’ll be getting for your money. Simply get in touch with our team and let them know the details of your site and we can get you an accurate quote, visiting in person if needed so you can get to know and trust us before work begins.

Intensive Testing With Detailed Reports

Choose a level of testing that suits your needs. Carried out to the latest regulations and highest standards, our testing gives you clear and extensive reports and makes you aware of any issues to follow up on. Some electrical testing companies only tick boxes – leaving you at risk of liability should something get missed. With us, you get more than just a certificate because you deserve a complete and reliable service.

Qualified & Experienced Engineers You Can Trust

With 20 years of expertise in the electrical and compliance industry, we’re experts in the electrical testing industry. Our hand-picked engineers are professional, reliable and have the right skills for the job.

Services offered by our in-house team

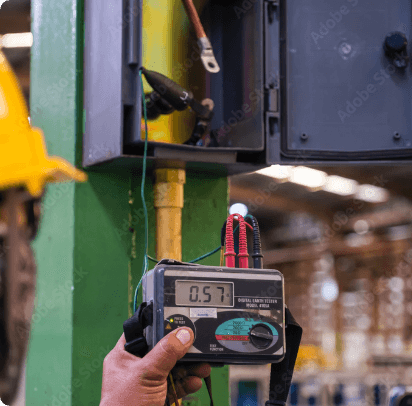

Portable Appliance Testing

Portable appliance testing or PAT is necessary for all electrical items used with or by a business. Whether you’re a mobile business taking equipment from venue to venue or you are a large company with monitors, coffee machines and printers, each item needs to pass a PAT.

Our PAT service gives you a clear tagged and logged inventory record (ITR) and adds any failed appliances to your asset list for audit.

Our team will do everything possible to minimise disruption to your business, such as not turning off power unnecessarily, so you can continue business as usual. Access all of your reporting and updates through a customer portal for simplicity and enjoy the peace of mind that your portable electrical appliances are compliant and safe.

Specifically

- PAT testing to be carried out to the latest regulations.

- Carry out minor maintenance work to rectify and provide a test and provide proof of faulty items.

- All items to be tagged and logged in an inventory test record (ITR).

- All work to be carried out with minimal disruption.

- Digital Report to include location, ID, description of equipment, all test details, visual test, pass/fail, date of next test and comments.

- All failed items added to your site asset list for audit

- Access via your customer Portal

Services offered by our in-house team

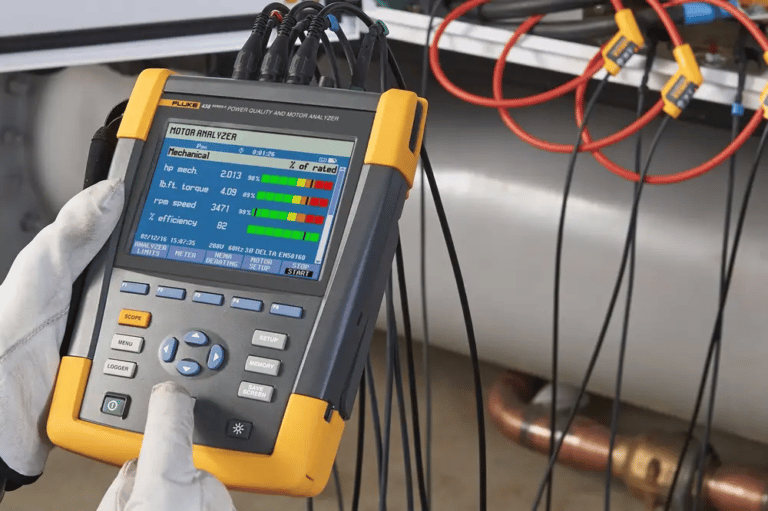

Load Analysis

Electrical equipment may degrade over time and you may notice:

- Your electrical bills are higher

- Equipment running hotter than usual

- Motors may make strange noises, indicating a pending problem

- Erratic and seemingly unrelated equipment failures throughout the building

Our load analysis testing shows you exactly where there may be stress on your power system and whether degrading electrical equipment needs fixing or replacing for safety.

By having a professional load analysis carried out by our technicians you can save money on electricity bills and catch issues with overheating, strange electrical noises or odd equipment failures around your building. These things might otherwise go uninvestigated and could lead to potentially bigger – more expensive – problems.

Our in-house team will investigate, monitor and report on all the relevant factors, giving you a clear report and debrief of their findings.

As part of an electrical load analysis we will collect data on power quality, the quantity used and often harmonic data to identify and locate electrical problems in your building’s distribution system. This is done when; Adding to an existing system and verifying the amount of electricity consumed.

As part of an investigation into:

- Over-Load Conditions

- Voltage Drops

- Load Imbalance Between The Phases

- Power Factor

- Load Profiles

- Harmonic Distortion Problems

Any of these issues can cause intermittent problems that can lead to strange equipment operations, unexpected failures and more.

Monitoring

Monitoring is done on the main conductors as well as the neutral and we follow proven engineering procedures to ensure the testing is non-intrusive, acacurate and safe. The duration depends on many factors including weather (air-conditioners are only used in the summer), production process and interaction between other equipment (i.e. heaters and ventilation motors).

Reporting

Our goal is to capture any potential problems in the electrical system as your equipment is in ause. Once the data has been gathered and collated for a loading profile, we will generate a report that includes:

- Voltage And Current

- Kw, Kvar And Power Factor

- Harmonics (If Required)

- Events

Outsourced Services

Services Provided By Our Partners

We use specific partners to provide these services with similar values and quality to our own. All the services are managed by us through our service desk.

Lightning Conductor Test

Our lightning conductor testing is carried out by our outsourced partners who share our values. Ensure the efficiency and safety of your building’s lightning conductor, adhering to British standards and providing an annual test.

You’ll receive a full defects report with suggestions for any remedial work that’s needed, all carried out safely and quickly so you can spend more time on what matters most to your business.

Specifically

- Provide Yearly Lightning Protection System Test

- Meets British Standards BS62305

- Full Defects Report Provided For Remedy.

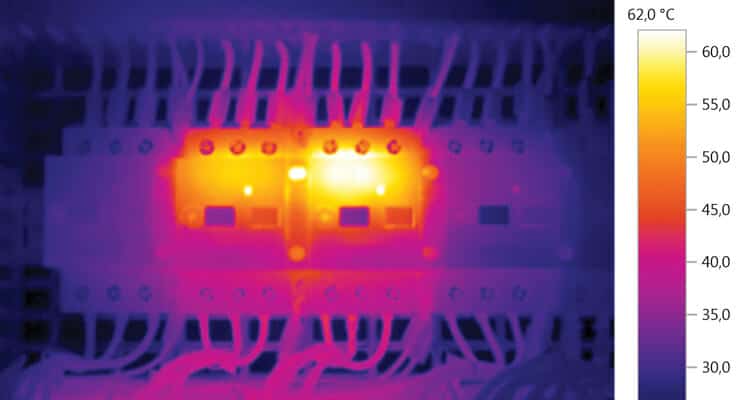

Thermographic Testing

Concerned you may have overloaded cables or poor connections? Thermographic testing could be the answer you’re looking for.

There are no other preventive maintenance techniques or technology that are capable of diagnosing these types of defects in your building, making thermographic testing uniquely useful if you suspect you might have issues with your wiring.

Thermographic testing is carried out by our partner who will give you an easy-to-understand report of your results, so you can take any action needed as soon as possible.

Electrical thermography is useful as there is no other preventive maintenance technology or technique that can identify defects such as poor connections, overloaded cables…

Hear From Customers Who Used Our Electrical Safety Services…

Success Stories

Kate Lester,

CEO - Diamond Logistics

John Pollard,

Facilities Manager - Whiteley Village

Malcolm Cooper,

Facilities Manager - PGS Exploration Plc

Sharon Griffiths,

Facilities Manager - Roxburghe Plc

Ian Rider,

Facilities Manager - The Corporation of Trinity

Mandy Walters,

Purchasing Mgr - Nicholson McLaren Engines

Janet Whittakeroe,

School Bursar - Christ Church Primary School

Jarard Cassem,

Director - Quatrefoils

Rochelle Latham,

Managing Director - Latham Smith

Stewart Mc Crae,

Director- Property Advisory Services Ltd

We Take The Time To Understand Your Needs, So You Get The Right Service For You

Book a call with our experienced and friendly team, here to listen to your individual needs so you can get the electrical safety services that will keep your business and building safe, protected and compliant…